Doosan Diagnostic Software DMS 5 3 1 3: Ultimate Truck Tool

Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.

Overview of Doosan Diagnostic Software DMS 5 3 1 3

Doosan Diagnostic Software DMS 5.3.1.3 is a powerful tool for monitoring and analyzing the performance of Doosan excavators and loaders. This software provides essential features and functions for optimal equipment management and maintenance.

Installation and Setup

Installing Doosan DMS 5.3.1.3 is a straightforward process that can be easily set up on the control units of Doosan machinery. The software ensures seamless integration with the equipment for accurate diagnostics and analysis.

Features and Functions

- Real-Time Data Visualization: Monitor the current status of the equipment with graphical sensor data display.

- Data Logging and Storage: Save critical data on the hard drive for future reference and analysis.

Compatibility with Doosan Models

Doosan DMS 5.3.1.3 is compatible with a wide range of excavators and loaders, allowing for detailed monitoring and comprehensive analysis of their performance. The software includes a complete list of fault codes for easy troubleshooting and resolution.

Using Doosan DMS 5 3 1 3 for Vehicle Diagnostics

Monitoring Equipment Status

Doosan DMS 5 3 1 3 enables real-time visualization of sensor data, allowing users to monitor the current status of their equipment efficiently.

Real-Time Data Visualization

The software provides graphical displays of sensor information, giving users a clear view of the equipment’s performance.

Data Logging and Storage

Data can be saved to the hard drive for further analysis, creating a comprehensive record of equipment operation.

Fault History Review

Users can review the history of faults detected by the software, helping to identify recurring issues and improve equipment reliability.

Error Code Identification

Doosan DMS 5 3 1 3 includes a detailed list of fault codes, making it easier to pinpoint the root cause of issues for quick resolution.

Troubleshooting Guidance

The software offers guidance on resolving equipment faults, assisting users in performing effective troubleshooting procedures.

Performance Analysis

By analyzing work patterns and maintenance practices, users can optimize equipment performance and ensure efficient operation.

Work Patterns Evaluation

Doosan DMS 5 3 1 3 helps assess how the equipment is utilized, allowing for adjustments to enhance productivity.

Equipment Maintenance Suggestions

The software provides maintenance recommendations based on performance data, aiding in prolonging the lifespan of the equipment.

Connectivity and Communication

Specific Communication Cable Requirements

To establish a seamless connection between the control unit and your PC, specific communication cables are needed. These cables ensure proper data transmission and communication for effective diagnostics.

Establishing Connection with Control Units

The process of connecting to the control units of your Doosan equipment is straightforward. Simply use the designated communication cable to link the excavator or loader to your computer, enabling data exchange and analysis.

Access Levels for Different Users

Doosan DMS 5.3.1.3 provides different access levels tailored to various user roles. Whether you’re a dealer, service provider, or developer, the software offers customizable permissions to suit your diagnostic and maintenance needs.

Benefits of Using Doosan DMS 5 3 1 3

Recommendation for Optimizing Equipment Functionality

When it comes to maximizing the functionality of your equipment, Doosan DMS 5.3.1.3 provides valuable insights and recommendations. By utilizing this diagnostic software, you can optimize your equipment’s performance and ensure efficient operations.

Advantages of Investing in Diagnostic Software DMS 5 3 1 3

Investing in Doosan DMS 5.3.1.3 offers numerous advantages for equipment operators and maintenance professionals. Some key benefits include:

- Enhanced Equipment Monitoring: The software allows for comprehensive monitoring of equipment performance, enabling proactive maintenance and optimization.

- Improved Performance Analysis: With detailed data visualization and analysis tools, users can identify patterns and trends to enhance equipment functionality.

- Efficient Troubleshooting: Doosan DMS 5.3.1.3 simplifies the troubleshooting process by providing error code identification and troubleshooting guidance.

Advantages of Investing in Diagnostic Software DMS 5 3 1 3

Investing in the Doosan DMS 5.3.1.3 diagnostic software brings numerous benefits to your operation. Let’s explore some of the key advantages:

- Comprehensive Monitoring: Gain access to detailed real-time data and performance analysis for enhanced equipment oversight.

- Efficient Troubleshooting: Quickly identify fault codes, review error histories, and receive guidance on resolving issues effectively.

- Optimized Performance: Evaluate work patterns, receive maintenance suggestions, and ensure your equipment operates at peak efficiency.

- Increased Productivity: By utilizing the advanced features of the DMS 5.3.1.3 software, you can streamline your workflow and maximize productivity.

- Cost Savings: Proactive monitoring and maintenance recommendations can help prevent costly downtime and repairs, ultimately saving you money in the long run.

![Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC](https://dtctrucks.com/wp-content/uploads/2024/04/1-1.webp)

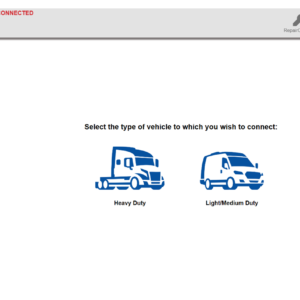

![Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC](https://dtctrucks.com/wp-content/uploads/2024/04/Captura-1.webp)

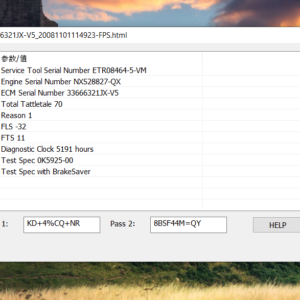

![Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC](https://dtctrucks.com/wp-content/uploads/2024/04/1-1-150x150.webp)

![Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC Doosan Diagnostic Software DMS 5 3 1 3 provides essential tools for monitoring and analyzing Doosan excavators and loaders via the E-EPOS controller. With real-time data visualization and fault history analysis, this software ensures optimal equipment performance and maintenance. Connecting to the control unit requires specific communication cables, offering different access levels for users, making it a vital tool for heavy machinery operators.DOOSAN DMS-5 3.1.3 [2023.11] diagnostic software 1PC](https://dtctrucks.com/wp-content/uploads/2024/04/Captura-1-150x150.webp)